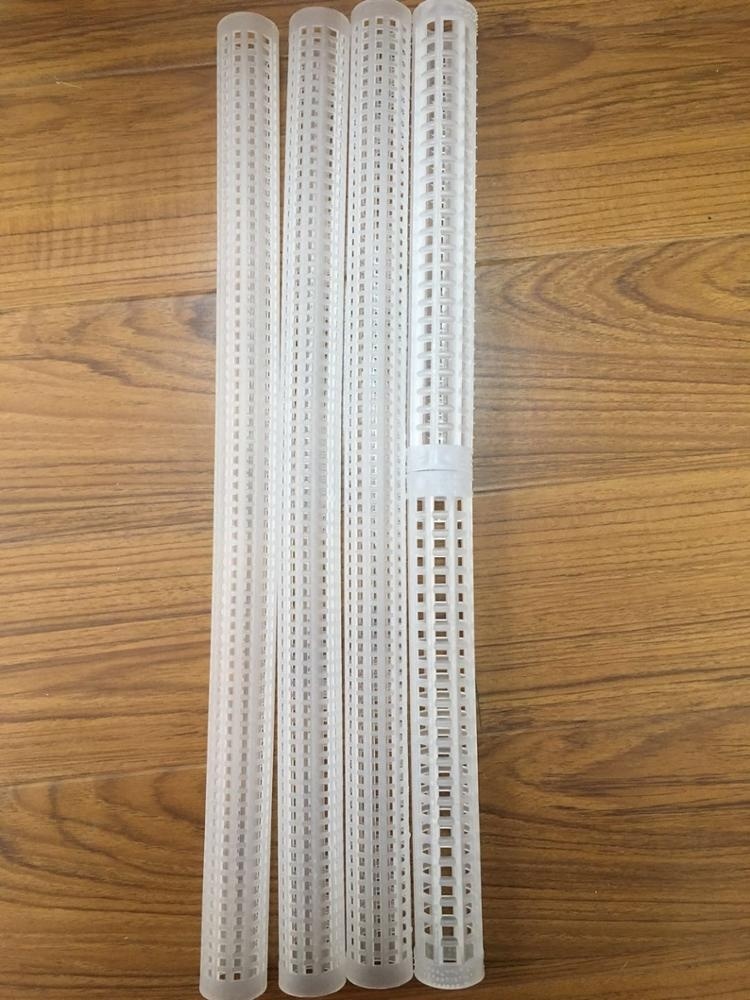

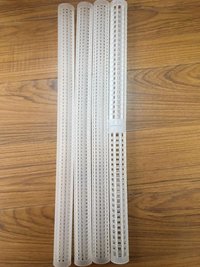

0.8g/m pp yarn water filter cartridge

Product Details:

- Material 100% Polypropylene

- Character Open End

- Properties Raw

- Usage Knitting, Weaving

- Attributes Other

- Weight 28 Kilograms (kg)

- Color White

- Click to view more

X

0.8g/m pp yarn water filter cartridge Price And Quantity

- 1000 Kilograms

0.8g/m pp yarn water filter cartridge Product Specifications

- Raw

- Other

- Open End

- White

- 100% Polypropylene

- 28 Kilograms (kg)

- Knitting, Weaving

0.8g/m pp yarn water filter cartridge Trade Information

- Shanghai,China

- Western Union, Paypal, Telegraphic Transfer (T/T)

- 10000 Kilograms Per Week

- 30 Days

- Yes

- Contact us for information regarding our sample policy

- 9paper cones/pp bag, also can be in carton or pallet packing

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Africa, Asia

Product Description

We use 100% Polypropylene material for producing pp yarn, not mix with some other materials.So quality is good and pure.

Our produced pp yarn for filter cartridge are mostly 0.5g/m, 0.8g/m, 0.9g/m, 1g/m and 1.1g/m, we also can produce pp core and filter cartridgeby ourselves.

We can produce this yarn in O/E, ring spun and friction(it is much lighter than O/E spinning and has much better filtering effect than O/E.)

Premium Raw Polypropylene Construction

Each 0.8g/m filter cartridge is crafted entirely from virgin polypropylene, offering superior chemical resistance and minimal fiber shedding. The raw material ensures that the cartridge is safe for use in applications requiring non-toxic, non-reactive components, making it ideal for water purification and industrial use.

Optimized for Knitting and Weaving Processes

The open-end design and balanced yarn structure make these cartridges perfect for integration into knitting and weaving operations. Manufacturers can rely on the even thickness and durability for consistent product quality during filter element production in a variety of filtration systems.

FAQs of 0.8g/m pp yarn water filter cartridge:

Q: How is the 0.8g/m PP yarn water filter cartridge typically used in knitting and weaving?

A: The cartridges open-end and uniform texture make it well-suited for incorporation into knitting and weaving processes, often to fabricate water filter elements or sleeves in industrial water filtration systems.Q: What are the main benefits of using 100% polypropylene for water filter cartridges?

A: Polypropylene is renowned for its excellent chemical resistance, low moisture absorption, and purity. These qualities ensure the cartridge efficiently filters particles without contaminating water, making it ideal for potable water and industrial applications.Q: When should I consider choosing raw PP yarn water filter cartridges over finished materials?

A: Raw polypropylene yarn is ideal when you require customization during the manufacturing process, such as adjusting cartridge dimensions or filter grades through knitting or weaving, ensuring tailored filtration solutions.Q: Where are these PP yarn filter cartridges typically manufactured and supplied from?

A: These cartridges are produced and exported by manufacturers in China, a global hub for high-volume, quality filtration materials, serving worldwide suppliers and OEMs in the water treatment sector.Q: What is the process for integrating the yarn into a finished filter product?

A: The raw yarn is incorporated into specialized knitting or weaving machinery to construct seamless filter sleeves or cartridges, which are then thermally bonded or assembled according to the desired filter specifications.Q: How does the cartridges weight and structure benefit manufacturers and exporters?

A: With each spool weighing 28 kilograms, manufacturers experience fewer changeovers and increased efficiency during production, while exporters benefit from shipping larger quantities in a cost-effective manner.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese